Diecast cars are highly collectible miniature replicas of real cars that have been produced for over a century. They are made using a process called die casting, which involves injecting molten metal into a mold under high pressure. In this blog post, we'll take a closer look at how diecast cars are made and the steps involved in the process.

The first step in making a diecast car is to create a design. This design is then used to create a mold, which is made from steel and consists of two halves that fit together to create a cavity in the shape of the car. The mold is carefully crafted to include all the details and features of the car, including the wheels, doors, windows, and other intricate details.

Once the mold is complete, the diecasting process begins. The metal used in diecasting is typically a combination of zinc, aluminum, and copper, and it is melted down in a furnace. The molten metal is then injected into the mold at a high pressure, which forces the metal to fill every detail of the mold. The metal cools and hardens quickly, and the mold is opened to reveal the finished product.

After the car has been removed from the mold, it is inspected for quality and any imperfections are corrected. The car is then painted and decorated to match the design of the real car it is modeled after. The paint is applied in a series of layers, with each layer adding depth and color to the car.

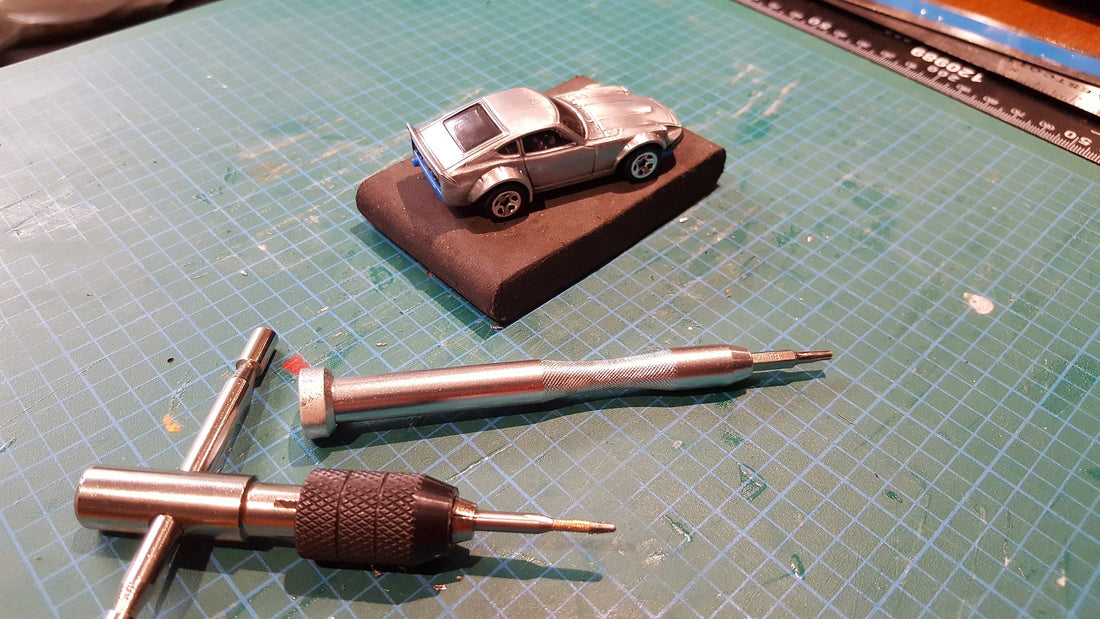

Once the car has been painted and decorated, it is assembled. This involves attaching the wheels, windows, and other parts to the body of the car. Some diecast cars have working features, such as opening doors, hoods, and trunks, and these features are also assembled during this stage.

The final step in the process is to package and distribute the diecast cars. Many diecast cars are sold as part of a collection or series, and they are often packaged in a box with a clear plastic window that showcases the car. Diecast cars can be purchased from a variety of retailers, including dedicated diecast car shops and online marketplaces like Amazon and eBay.

In conclusion, diecast cars are made using a process called die casting, which involves injecting molten metal into a mold under high pressure. The metal cools and hardens quickly, and the car is then painted, decorated, assembled, and packaged for sale. To find the best deals and widest selection of diecast cars, search online and browse through marketplaces like Amazon, eBay, and dedicated diecast car retailers.